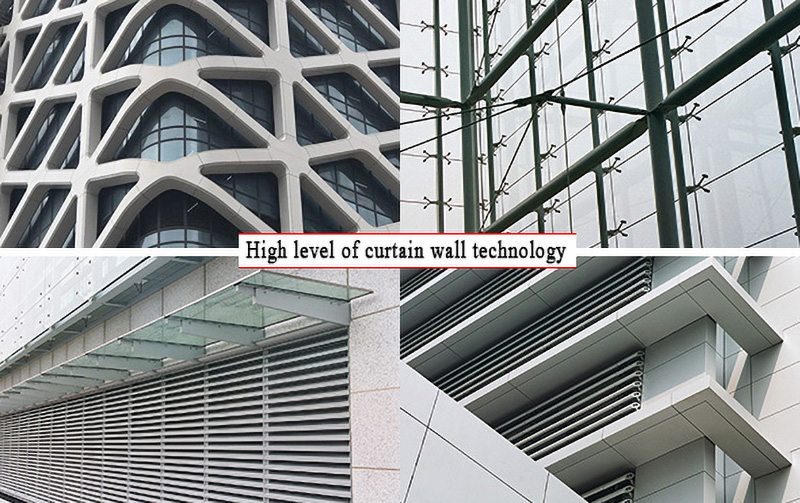

Construction Support for Curtain Walls, Doors, and Windows

Construction Support

The construction of curtain walls, doors, and windows requires a structured, multi-disciplinary approach to ensure that these systems are installed correctly, safely, and perform well over time. These elements of a building’s facade are critical for both aesthetic appeal and functionality, serving to regulate thermal comfort, light, acoustics, and weatherproofing while also contributing to the building’s overall energy efficiency and safety.

Any concerns about curtain wall construction?

1. Lack of qualifications and strength, poor ability to perform contracts?

2. No professional construction team, don’t know how to start curtain wall construction?

3. Want to build a curtain wall but don’t know how to do it?

4. Is the price of curtain wall too high?

5. How many times has the curtain wall construction been transferred? Is there no dedicated person to coordinate?

6. Who will do the post-maintenance of the finished curtain wall?

ZD Curtain Wall specializes in curtain wall and door and window services

Standardized curtain wall construction allows you to worry-free about the quality of curtain wall construction

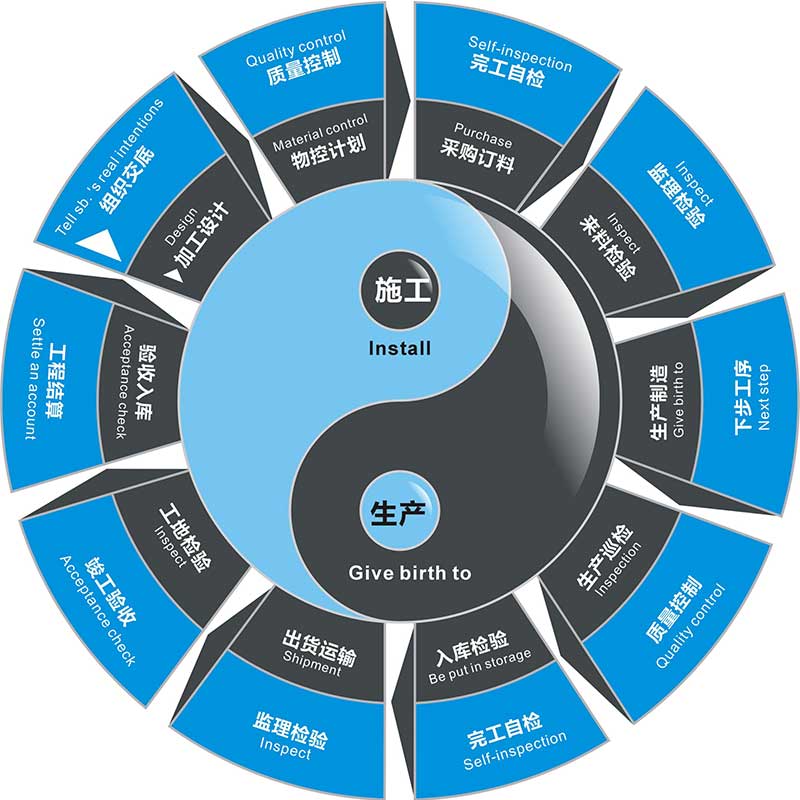

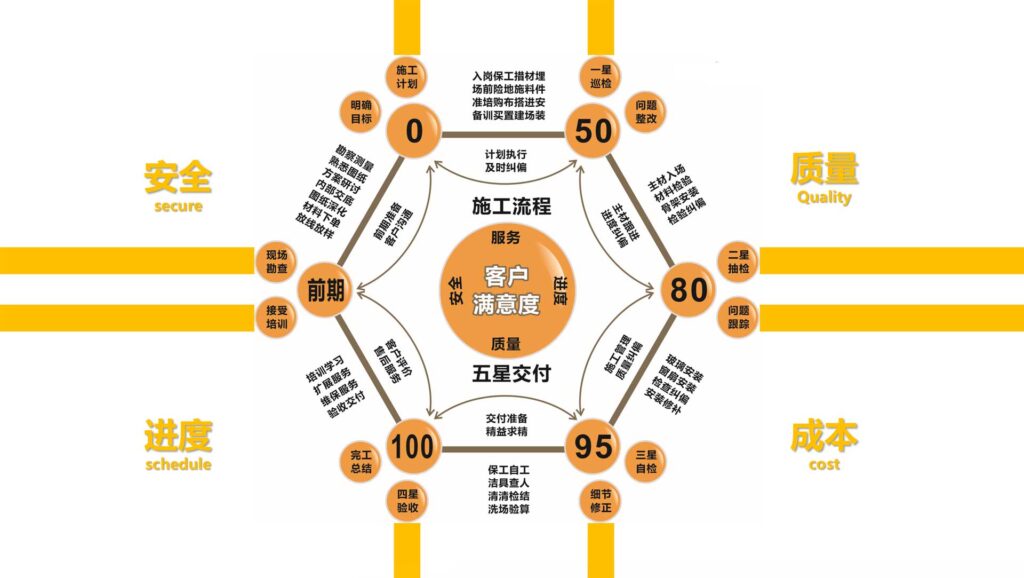

Standard process of curtain wall construction

01. Preparation before curtain wall construction

Understand the project overview: be familiar with the relevant information of the civil construction unit and the supervision company, be familiar with the power supply, water source, vertical transportation, external scaffolding, etc. for construction, prepare complete design and construction drawings, be fully familiar with the drawings, and prepare various technical standards, specifications, various records, inspection forms, etc.; Preparation of construction machinery: propose a plan for the use of the required machinery (specific to model, quantity, supply time, etc.), submit it to the warehouse and procurement department, prepare or purchase in advance, and ensure that all the equipment required for construction is in place.

02. Measurement and layout of curtain wall columns

The positioning and layout of columns is carried out after the formal design drawings have been determined and all error handling plans have been determined. Positioning and layout of columns is a key step in curtain wall installation. The size of the error directly affects the installation quality of each subsequent process. Positioning and layout of columns requires comprehensive consideration of issues, including the size processing of each corner and node, and the specifications of the glass, the direction of the sealing, and the installation direction of the columns. Process flow:

Prepare the layout tools → find the position of the opening line on site → draw the horizontal line on the key layer → find the column layout positioning point → add the fixed position → pull the horizontal line → check the error of the horizontal line → adjust the error → perform horizontal segmentation → review the error of the horizontal segmentation → hang the vertical line → check the verticality → fix the vertical line → check the accuracy of all layouts → focus on checking the layout of the corners and the position of the variable surface.

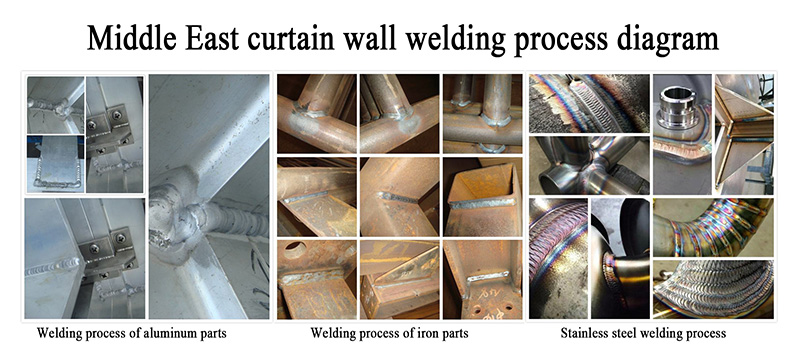

03. Installation of buried plates and steel supports

Before entering the construction site, the galvanized steel angle code must be fully inspected to ensure that all materials meet the requirements. Unqualified semi-finished products shall not enter the construction site, let alone be installed. Transition used in the construction process

Process flow:

Prepare materials → Put materials in place → Check quality → Clean the connectors → Install → Adjust → Tighten.

04. Curtain wall column installation

Curtain wall column process flow:

Check the column model, specification and quantity → Put in place → Insert the core sleeve at the lower end of the fixed beam → Bolt the upper end of the beam to fix → Adjust in three dimensions.

05. Column reinforcement and secondary anti-corrosion

Treatment

Process operation

Construction preparation → Make a plan → Technical disclosure → Install temporary beams → Reinforcement → Acceptance → Secondary anti-corrosion treatment.

06. Beam installation

Beam installation includes three parts: one is the installation of beam angle code; the second is the installation of beam vibration washers; the third is the installation of beams. These three parts are fixed once by stainless steel bolts penetrating the columns. In addition, the installation of beams still needs to consider aesthetics.

Process operation flow:

Construction preparation → Check the quality of each material → Install in place → Check.

07. Fireproof layer installation

Main materials:

Fireproof partition board, nails, nail bullets, fireproof rock wool. Fireproof partition board is made of galvanized steel plate processed and made in the workshop. During installation, nails and rivets are used to connect the main structure and curtain wall structure to separate the upper and lower layers.

Process operation

Preparation work → Arrange the fireproof joints → Test installation → Check tools → Punch holes → Rivets → Nail in place → Check installation quality.

08. Installation of glass panels

The glass panels are installed at the construction site after being processed by the processing plant. Since it is not suitable to store glass for a long time at the construction site, a detailed installation plan should be made before installation, and a detailed glass supply plan should be listed, so as to ensure smooth installation and facilitate the workshop to arrange production.

Installation process

Construction preparation → Check and accept the glass panels → Stack the glass panels in layers → Initial installation → Fix → Acceptance.

09. Installation of fireproof cotton and thermal insulation cotton

In order to meet the requirements of fireproof performance and thermal insulation and energy saving of curtain walls, fireproof and thermal insulation measures must be considered in curtain wall design. In addition to installing fireproof partition boards, 50mm thick thermal insulation cotton should be filled in the panels.

Process flow

Fireproof rock wool size measurement → Cutting according to size → Pressing → Fixing → Checking and repairing → Hidden acceptance.

10. Weather-resistant sealant injection for curtain wall

After the glass and other panels are installed and adjusted, sealant injection begins. This process is a key process to prevent rainwater leakage and air infiltration. The sealing treatment of the joints at the four corners of the open window frame is also a part that needs to be carefully worked on.

(II) Process operation flow:

Fill the pad rod → clean the glue injection seam → paste the scraper paper → inject sealant → scrape the glue → tear off the scraper paper → clean the finishing layer → check and accept

11. Curtain wall cleaning

Curtain wall cleaning is the last process before project acceptance. Although the installation has been completed, this process cannot be sloppy in order to achieve perfect finishing quality.

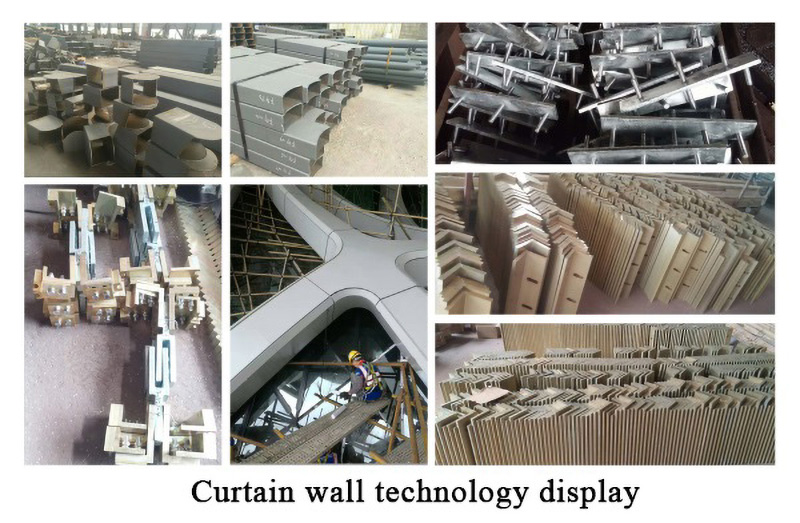

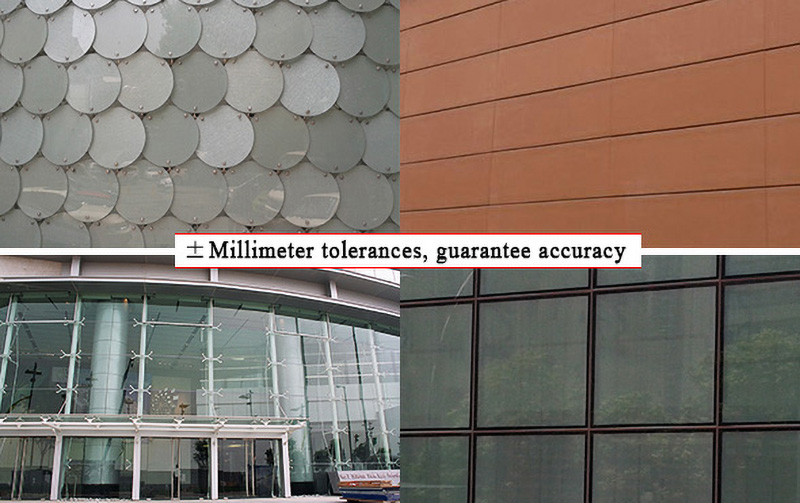

Engineering process details

Focus on every detail and polish every inch

Conclusion

Guiding a client through the curtain wall installation process requires a methodical approach, with careful attention to each step of the procedure. From the layout and embedded parts installation to frame assembly, glass placement, sealant application, and final acceptance, each stage plays a crucial role in ensuring the curtain wall system’s performance, durability, and aesthetic appeal. By following these detailed steps, the project can be completed efficiently, on time, and to the highest standards.

The Team

Our Experts

Lan Longbing

Director

Liao Jianwei

Designer

Xia Wenjia

Designer

Maria Jay

Designer

Zhou Huan

Construction Director

Zhao Shanrui

Construction team leader

Zeng Ge

Construction team leader

Huang Daxin

Construction team leader

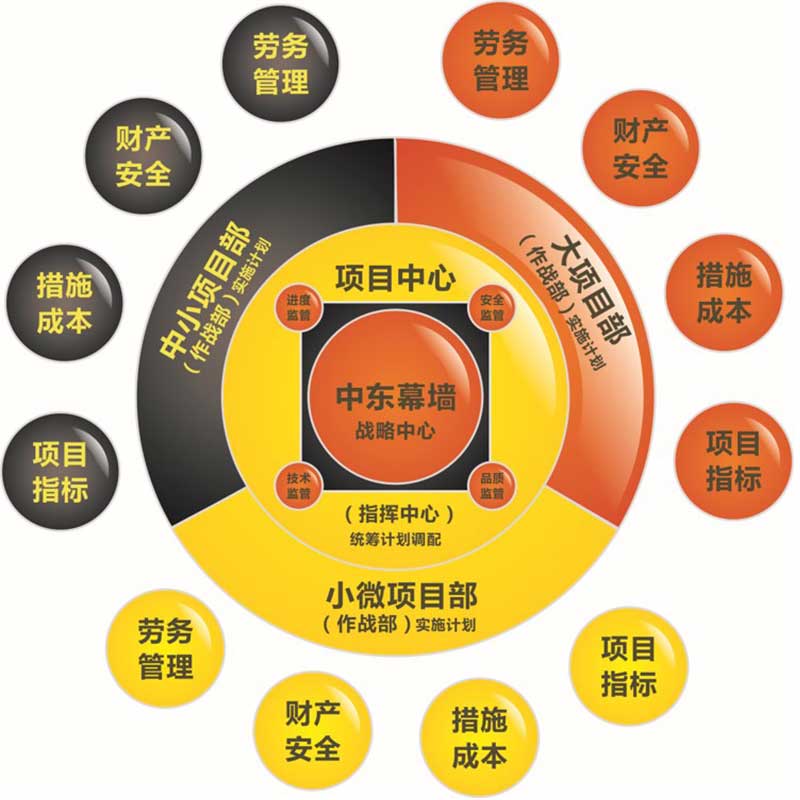

Construction Management

- Precision and Customization: Achieving the desired aesthetic while ensuring structural and environmental performance requires high precision in both design and installation.

- Logistical Complexity: Managing large, heavy, and fragile materials requires careful planning for transportation, storage, and handling on-site.

- Weather and Site Conditions: External weather conditions (e.g., rain, wind, or extreme temperatures) can delay installation. Furthermore, site-specific challenges like irregular building shapes or hard-to-reach areas may require specialized solutions.

- Performance Standards: Curtain walls, doors, and windows must meet stringent building codes and performance criteria (e.g., energy efficiency, thermal insulation, soundproofing, fire safety, etc.), which require continuous coordination with architects, engineers, and manufacturers.

Quality Control

- People: Post personnel management mechanism

- Machine: Management measures formachinery and equipment

- Law: Quality and safety management

- Material: Tracking production quality throughout the process

- Measuring: Supervision of construction indicators throughout the process

Tailored to Your Needs: Custom doors and windows are built to your specific requirements in terms of size, style, material, and performance, ensuring they meet your exact needs.

Enhanced Aesthetic Appeal: With custom design options, you can create unique features that match the overall aesthetic of your home or building, whether traditional or contemporary.

Increased Energy Efficiency: Custom doors and windows can be designed with energy-saving features, reducing heating and cooling costs and improving comfort.

Improved Functionality: Custom solutions offer greater flexibility to enhance ventilation, accessibility, or security, depending on the function of the space.

Higher Property Value: High-quality, well-designed custom doors and windows can add to the overall value of your property by enhancing both its curb appeal and functionality.

Construction Process

6 Steps To Cooperation

01.

1. Project research

Project situation, project size, location

02.

2. Design and construction plan

Bill of Quantities, Project Drawings, Product Information Confirmation

03.

3. Scheme confirmation

Construction plan, budget evaluation and quotation

04.

4. Construction preparation

Technical support, survey and design, material ordering

05.

5. Construction and guidance

Send personnel to the site to support construction

06.

6. After-sale service

The goods are usually packaged and transported or delivered according to the client’s requirements.

Send A Message

Contact Info

Call Us

+86-17727814139

+86-755-27386668

Our Email

monikachenwall@gmail.com

Our Location

14F, Building 1, No. 35, Guangtian Road, Yanluo Village, Baoan District, Shenzhen

Working Hours

Mon-Fri: 8AM-22PM

Sat-Sun: 8AM-20PM