A steel structure engineering curtain wall refers to a type of curtain wall system that uses steel framing as the primary support structure for attaching glass, metal, or other cladding materials. Steel curtain walls combine the strength and durability of steel with the aesthetic flexibility of modern façade materials, often resulting in sleek, high-performance, and architecturally striking building envelopes.

Types of Steel Curtain Walls

- Stick-Built Steel Curtain Wall:

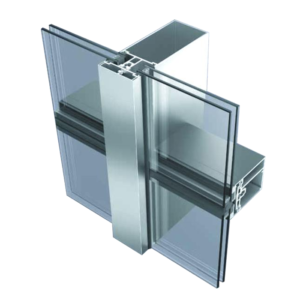

- In this system, the steel framing components (such as mullions, transoms, and anchor bolts) are assembled piece by piece on-site, and glass or other cladding materials are then installed.

- Advantages: Customization on-site, flexibility for unique or irregular building shapes.

- Disadvantages: Longer installation time and greater reliance on skilled labor.

- Unitized Steel Curtain Wall:

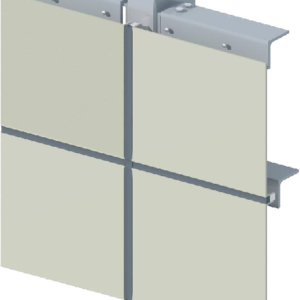

- Pre-fabricated in large, pre-assembled panels at a factory, which include the steel frame and cladding materials (typically glass or metal). These panels are then delivered to the construction site and installed as large units.

- Advantages: Faster installation, high-quality control, and fewer on-site labor requirements.

- Disadvantages: Limited customization after panels are fabricated.

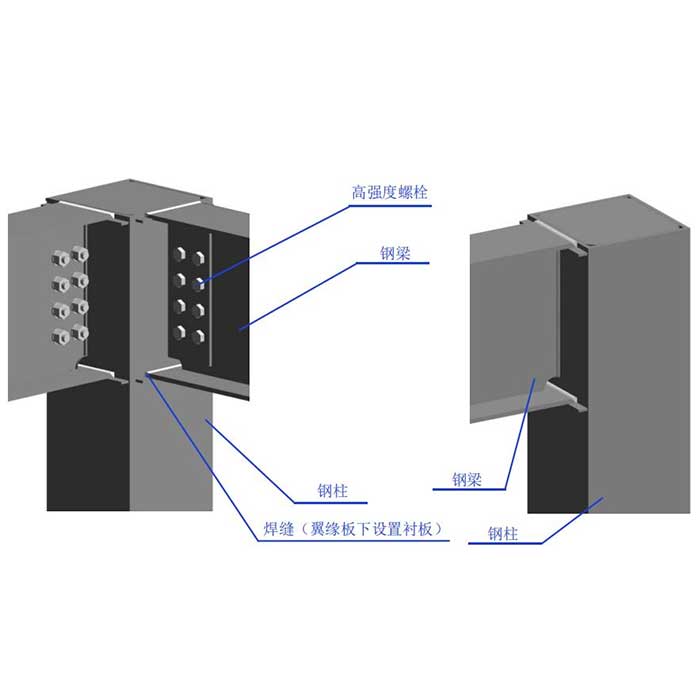

- Structural Steel Curtain Wall:

- A highly engineered system in which the steel structure not only serves as the support for the curtain wall but also as part of the overall load-bearing structure. This system is often used for buildings where the curtain wall needs to be integrated more directly with the building’s structural framework.

- Advantages: Excellent for high-rise buildings and structures with demanding engineering requirements.

- Disadvantages: More complex and expensive than typical curtain wall systems.

Installation Process

- Site Preparation and Structural Design:

- Detailed engineering design and planning are essential to ensure the curtain wall system is properly integrated with the building’s main structure. This includes wind load analysis, thermal performance requirements, and seismic considerations.

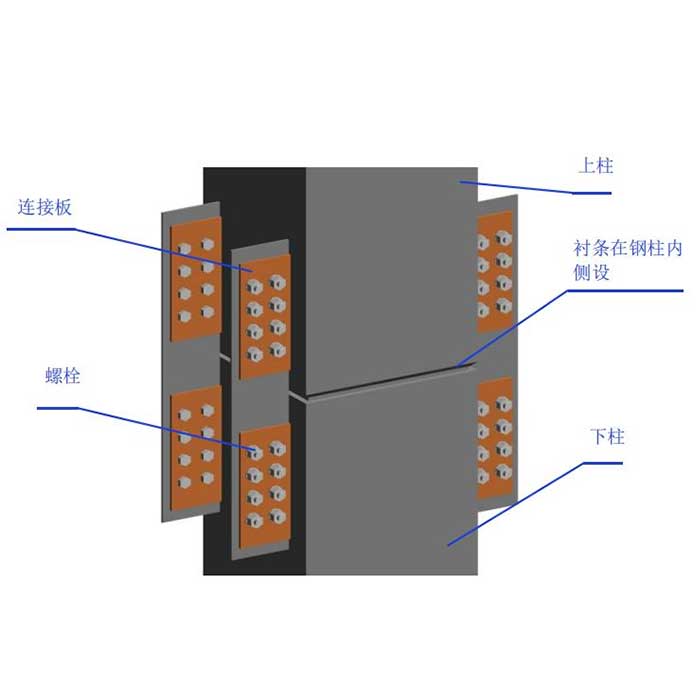

- Fabrication of Steel Frame:

- The steel frame is fabricated off-site in a factory or workshop. The frame is usually made from high-strength steel, and it can be coated or treated for corrosion resistance (e.g., galvanization or powder coating).

- Glazing or Cladding Installation:

- Once the steel structure is installed, the cladding material—typically glass, metal panels, or stone—is attached. In many cases, glass is the dominant cladding material, which is either framed or held in place by gaskets or silicone sealants.

- Sealing and Weatherproofing:

- Proper weatherproofing and sealing are crucial to ensure that the steel curtain wall system is airtight and waterproof. This is often done using specialized gaskets, caulking, and weather-resistant seals.

- Inspection and Final Touches:

- After installation, the curtain wall is carefully inspected for structural integrity, sealing, and any defects in the material or installation. Maintenance instructions and warranty details are typically provided to ensure the longevity of the system.

Applications of Steel Structure Engineering Curtain Walls

- High-Rise Buildings:

- Steel curtain walls are commonly used in high-rise and skyscraper construction because of their ability to withstand extreme wind loads and their capacity to hold large, expansive glass panels that provide panoramic views.

- Commercial Buildings:

- Office buildings, retail centers, and hotels often feature steel curtain walls, as the material allows for flexibility in design while providing a high degree of safety and functionality.

- Cultural and Institutional Buildings:

- Government buildings, museums, libraries, and other institutions frequently use steel curtain walls for their aesthetic appeal, structural integrity, and ability to support large-scale glass facades.

- Mixed-Use Developments:

- Steel curtain walls can be found in mixed-use complexes, where residential, commercial, and recreational spaces are integrated. They offer a seamless transition between different building functions and create a modern, cohesive look.

- Weight: The weight of stone can require stronger structural support and more complex installation techniques.

- Cost: Stone curtain walls can be expensive compared to other types of cladding materials, such as glass or metal.

- Limited Flexibility: Stone is rigid and not as adaptable to structural movement, which can be a limitation in some buildings.

Conclusion

Steel structure engineering curtain walls are a versatile and highly durable choice for building façades, particularly in high-rise, commercial, and institutional projects. With their ability to withstand extreme environmental conditions, provide aesthetic flexibility, and offer energy efficiency, they are widely used in modern architecture. While installation and material costs can be high, the long-term performance and aesthetic benefits often outweigh the initial investment.

评价

目前还没有评价